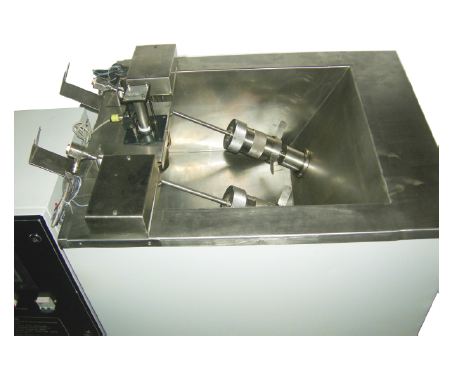

ROTATING PRESSURE VESSEL OXIDATION TEST APPARATUS

Code: 11027

COMPLIANCE

Conforms to ASTM D 2272, D 2112, D 4742, IS:1448 (P-65), IP - 229

APPLICATION

To Test Oxidation Stability of Steam Turbine Oils, Mineral Turbine Oils, Gasoline Automotive Engine Oils, Inhibited Mineral Insulation Oils by ROTATING PRESSURE VESSEL OXIDATION TEST METHOD.

We are also available on Whatsapp between 11 am to 6 pm

INSTRUMENT & CONSTRUCTION

Consists of a SS pressure vessel with a takeoff for pressure gauge, which is rotated at a fixed speed of 100RPM at an angle of 30° in an SS oil bath with a driven carriage, at high temperature. The sample is placed in a glass container with a teflon lid inside the vessel with oxygen and a copper catalyst. The point at which the pressure suddenly drops is called the induction point. The outer of the bath is made of powder coated CR sheet.

P.CODE MODELS DESCRIPTION

11027-00 RPVOT-1B Basic Model Single test with analogue pressure gauge

11027-01 RPVOT-2B Basic Model Double test with analogue pressure gauge

11027-02 RPVOT-1A Fully Automatic model single test

11027-03 RPVOT-2A Fully Automatic model Double test

SAFETY & SALIENT FEATURES

The system has a variety of Safety features for both the user and test like

a. Auto-cutoff on oil level low,

b. Test abort with alarm, if temperature not attained within set time.

c. Test abort with alarm, if temperature overshoot beyond high set.

d. Test abort with alarm, if Rotation not restarted within set time.

e. Test abort with alarm, if failure of carriage rotation.

f. Test abort with alarm, if carriage motor failure.

g. Test abort with alarm, On initial pressure drop.

h. No special software required to operate or interface the system.

STANDARD FEATURES

* Bath Precisely controlled to 0.10C

* Stainless steel pressure vessel with Borosilicate glass beaker, Teflon cover and copper catalyst.

* Temperature Range : Above ambient to 2000C

* Temperature and pressure Units can be varied by the user.

* Carriage rotated by a heavy duty Ac motor at 100+5 RPM

* Automatic Detection of end point and end of test for both RPVOT and TFOUT tests.

* Automatic Charging Pressure correction vs temperature

* End of test on INDUCTION OR TIME base

* Pressure charging with automatic temperature compensation provision inbuilt.

ECO FREINDLY FEATURES

* Dual heater system saves power by reducing the overall power

consumption

* Inbuilt memory 2GB for data recording saves on additional printer and paper cost.

* The Pressure sensor derives power from the system itself, hence no

batteries required.

* Automatic end of test if leak detected in the pressure vessel.

* Inbuilt stirrer eliminates additional motor for stirring saving power and maintenance.

SPECIAL FEATURES of THE CONTROL CONSOLE

a. The user console is colour touch screen based with 2GB internal

memory.

b. The unit is LAN Ready, enabling control of the system operation from any PC in your network.

c. Both TFOUT & RPVOT tests can be conducted

d. The test can be conducted even in time mode for batch testing. Saving precious time and power.

e. Any non compliance to the mandatory test conditions laid out in the

standard is detected, reported in the final report and the test aborted

f. Can handle upto 12 test stations. The units can be of any make.

STANDARD ACCESSORIES

11027-00 Test Bath with carriage, cover and support

11027-06 Test vessel

11027-07 Glass container

11027-08 Container lid made of Teflon

11027-09 Copper Catalyst

11027-10 Glycerine filled Pressure Gauge

OPTIONAL ACCESSORIES

11027-11Oxygen regulator

11027-12 Temperature and pressure recording device with

usb based pc interface.

11027-13 Spare Heater

11027-14 Flat ‘O’ ring

11027-15 Top ‘O’ ring

11027-16 Mandrel for making catalyst

11027-17 Spare Charging valves

xxxx-xx Bath Oil

ADDITIONAL OPTIONAL ACCESSORIES for 11027-02/03

11027-18 Spare Boost Heater

11027-19 Spare Pressure Sensor with coupling

11027-20 Spare charging line

11027-21 Double Stage Oxygen regulator